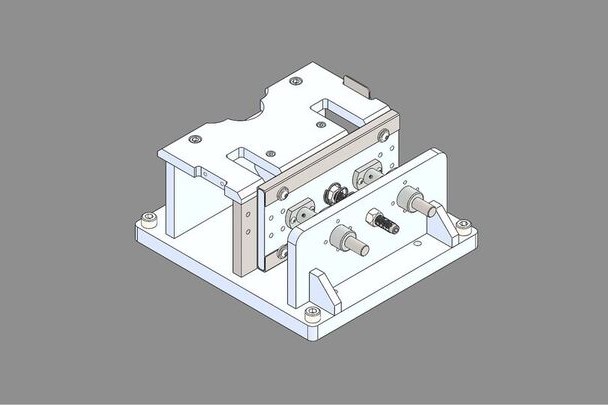

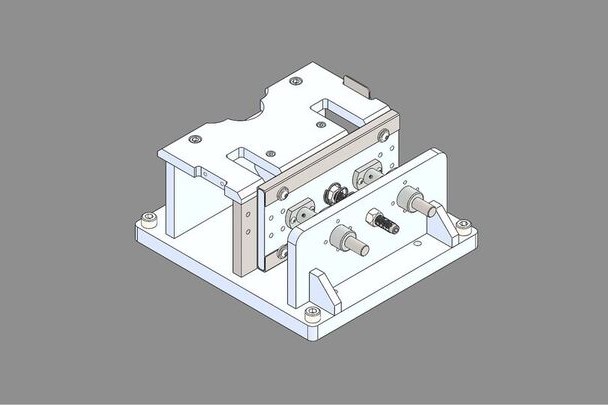

► Developed product showcase animations to effectively communicate and showcase conceptual design to stakeholders.

► The animations provide stakeholders with a realistic look of a concept during presentations, ensuring comprehensive understanding of the design.

► Conducted SolidWorks training and provided best practices for fabrication and 3D printing to a crowd of 90, primarily targeting factory personnel.

► The initiative aims to alleviate workload on the engineering team which improves productivity and efficiency within the department.

► Set standards to machine component used across all factories by studying and pinpoint crucial data and criteria required to mitigate product defect and customer complaints.

► Formulated guidelines to follow and new data points to collect for engineers and QA/QC personnel for data collection.

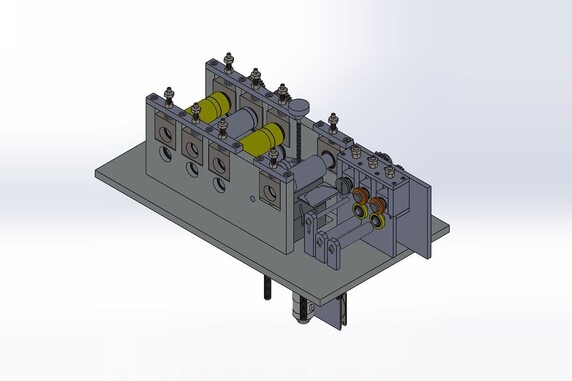

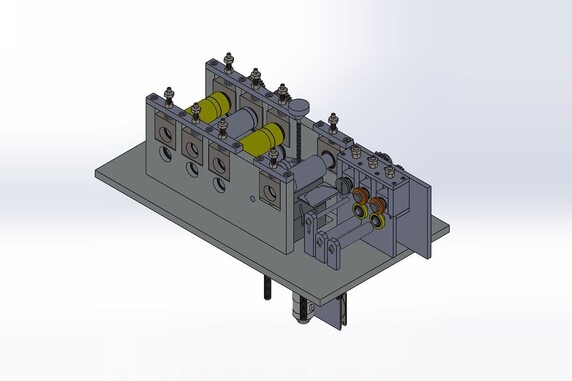

► Leveraged data collected within an automated Excel framework to design a QC jig for machine component and implement QA/QC standards across the assembly pipeline.

► Enhanced the design of facemask production machine through a strategic simplification approach.

► Improved product quality, minimized machine downtime and reduced maintenance costs.